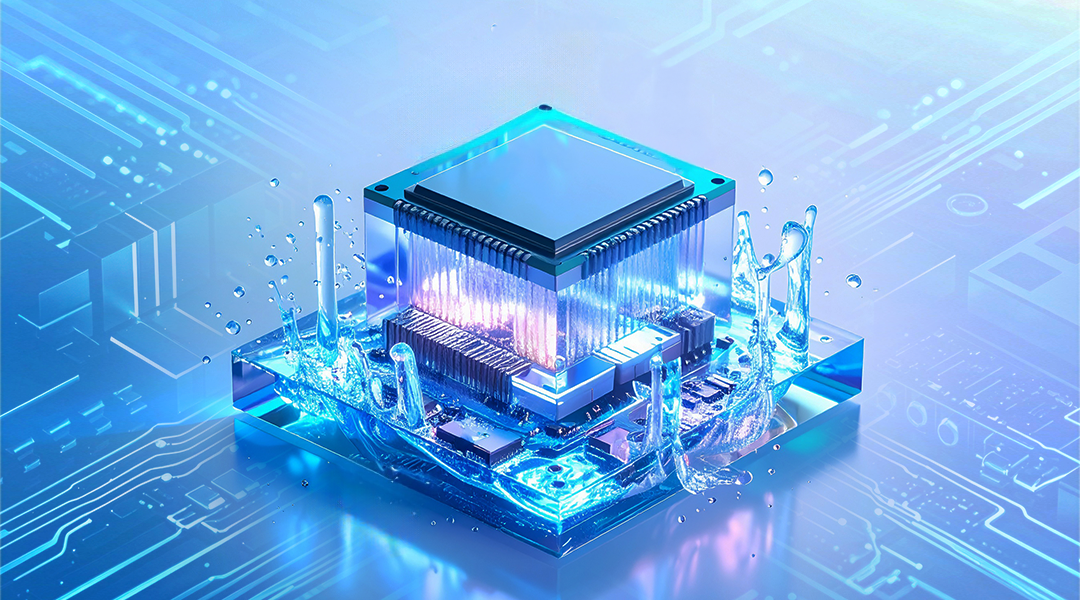

The power burden caused by the spread of AI is increasing. The cooling solution is liquid immersion.

According to the Uptime Institute, a global data center standards organization, power consumption per server rack (a single room containing servers) in a typical data center remains at 7–10 kW. However, the proliferation of AI and high-performance computing (HPC) is driving the adoption of high-density racks exceeding 20 kW. Deloitte, a global consulting firm, predicts that power consumption per rack could exceed 30 kW and even 60 kW in some environments. The International Energy Agency (IEA) reports that approximately 40% of data center power is used for cooling, demonstrating that cooling has emerged as a key variable in infrastructure design in the era of AI proliferation, going beyond mere operational considerations.

Among these, a solution gaining attention is immersion cooling. Immersion cooling directly immerses the entire server in an insulating fluid. Compared to conventional cooling methods, it offers superior heat absorption efficiency and added value, including simplified configuration, reduced noise, and optimized space utilization.

Global goes beyond diffusion and verification to economic design.

In the US and Europe, companies like Microsoft and Meta are expanding research into next-generation cooling technologies. Microsoft is expanding liquid immersion cooling from proof-of-concept (PoC) testing to real-world operating environments to verify technological reliability and operational stability. The Open Compute Project, an industry standards organization, is also standardizing server hardware, cooling fluids, and operating standards, laying the institutional foundation for industrial adoption.

In China, Alibaba applied single-phase immersion cooling to reduce its power efficiency index to 1.05–1.07, reducing power consumption by approximately 36%. Furthermore, a seawater-based underwater data center has entered commercial operation in the Hainan (Sanya) waters. While this method differs from traditional immersion cooling, the commercial operation experience of immersion cooling demonstrates its feasibility even in large-scale environments, suggesting potential for the long-term expansion of immersion cooling.

The overall data center cooling market is now moving beyond the stage of securing technological confidence. After major companies have proven reliability through demonstrations, structural design focused on economic feasibility and return on investment is emerging as a key challenge. This means the focus is shifting beyond experimental trials to implementing real-world operational models. Therefore, future expansion will depend not on mere technological feasibility but on the ability to establish realistic and standardized design and operational models.

The country has secured the technology, but is still developing the system and structure.

The domestic data center industry also has the technological foundation to adopt liquid immersion cooling. GS Caltex has developed Kixx Immersion Fluid S, Korea’s first liquid immersion cooling fluid, and is conducting demonstrations with Samsung Electronics, Supermicro, and LG Uplus. In addition to GS Caltex, major domestic and international data center and lubricant companies are also conducting demonstrations to verify the cooling efficiency and stability of liquid immersion cooling technology.

However, the spread of domestic immersion cooling faces two structural limitations.

- High Flash Point Regulations: Korea requires the flash point (the temperature at which ignition occurs) of refrigerant to be 250°C or higher, while the US and Europe allow flash points below 100°C. This difference necessitates the development of specialized fluids with enhanced safety in Korea.

- Separation of Operations and Service Entities: The domestic data center market typically has a structure where facility operators and service providers are separated. In this situation, facility investment and incentives for improving operational efficiency are not directly linked. This can slow the introduction of new cooling equipment.

Therefore, while the domestic market has secured technological capabilities, it will need to address the dual challenges of institutional standards and business structure before it can move into the full-scale expansion phase.

Why are lubricant companies leading the way in liquid immersion cooling?

Immersion cooling fluids must simultaneously meet insulation, a high flash point, oxidation stability, viscosity stability, and long-term durability. These requirements are not simply performance indicators; they are directly related to ensuring electrical safety, mitigating fire risks, and maintaining performance over long periods of operation. Chemical stability and viscosity maintenance, even under temperature fluctuations and in long-term operation environments, are particularly essential for data center servers, electric vehicle batteries, and energy storage systems (ESS).

These characteristics are technically intertwined with lubricant development. Lubricants have been developed with stability, oxidation inhibition, viscosity control, and long-term durability in high-temperature, high-pressure, and high-load environments as a prerequisite. Lubricant companies can extend their existing refining and additive technologies and reliability verification systems to the development of liquid immersion cooling fluids. This allows them to position themselves not simply as material suppliers, but as reliable cooling fluid technology providers that meet industry-specific needs.

GS Caltex’s first liquid immersion coolant meets standards and is proven through practical testing.

Liquid immersion cooling fluids require basic insulation, a high flash point, oxidation stability, viscosity stability, and long-term stability. Furthermore, during the market expansion phase, safety, environmental regulatory compliance, global standard compliance, and verification of proven data must be met.

GS Caltex’s Kixx Immersion Fluid S series is the first immersion coolant in Korea to meet these conditions.

- Ensured Safety: Combining PAO-based synthetic oils, esters, and bio-based raw materials, it meets the flash point of 250°C or higher and high insulation, meeting the standards required for data center fire safety and equipment protection.

- Meets environmental requirements: NSF food-grade certification and biodegradability requirements enable compliance with domestic and international ESG regulations.

- Guaranteed long-term stability: Maintains viscosity and oxidation stability to minimize performance degradation even in long-term operating environments.

- Standard Compliance: Meets the requirements of the Open Compute Project (OCP), an industry standards organization, ensuring compatibility with global server hardware.

- Securing Proven Case Studies: Through collaboration with Samsung SDS, Supermicro, and LG U+, we demonstrated cooling efficiency and server stability. This demonstrates reliability beyond technological development, backed by real-world operational data.

Through these conditions and verification, GS Caltex is solidifying its position in the liquid immersion cooling market based on reliability and regulatory responsiveness.

Beyond technology, structural design determines competitiveness.

Liquid immersion cooling is a next-generation thermal management technology that improves power efficiency and space utilization, and even influences equipment lifespan and carbon management. It is expanding beyond data centers to encompass mobility and the energy industry, and is expected to become a key pillar of the thermal management market. While expansion is possible, market leadership is not simply determined by technology ownership. Structural capabilities are required to design solutions that address regulatory compliance, including flame retardancy and safety verification; ensure compliance with international standards encompassing data centers and battery equipment; and secure empirical data under long-term load and charge/discharge conditions.

GS Caltex is developing Korea’s first liquid immersion coolant based on its lubricant technology. It is also preparing for the next phase of growth by addressing regulations, ensuring compliance with standards, and accumulating empirical data. Simultaneously, the company is pursuing the development of specialized products aligned with future demand sources, such as electric vehicle batteries, rapid charging infrastructure, and energy storage systems (ESS).

While technology may be secured, only companies that lead in structural design will set the standard for the future thermal management industry and secure the initiative for market expansion.